Grade 8 Sub Assemblies EN1677-4

Hackett Grade 8 components are manufactured from alloy steel in accordance with EN1677. All forged components are individually magnaflux crack detected after heat treatment, they are then individually proof load tested to 2.5 times working load limit in accordance with EN1677. Only components fully compliant with all aspects of EN1677 can be used in chain slings certified to EN818-4. Hackett Grade 8 lifting components are suitable for use in a temperature range of -40°C up to 200°C without reduction in working load limit, reductions apply up to 400°C.

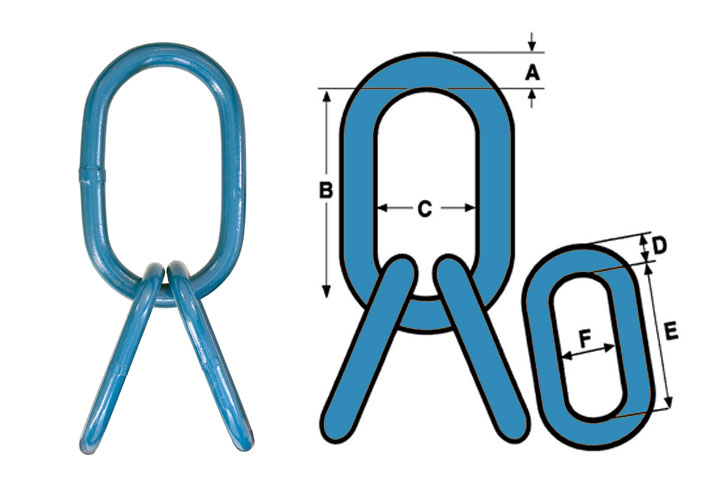

TECHNICAL SPECIFICATION

| Part Code |

Chain Size mm |

A mm |

B mm |

C mm |

D mm |

E mm |

F mm |

WLL tonnes |

Mass Kg |

CAD Files |

|---|---|---|---|---|---|---|---|---|---|---|

| X-007-06 | 6 | 16 | 140 | 70 | 14 | 110 | 60 | 2.9 | 1.45 | Format ProEngineer Solidworks Parasolid Iges Step Sat |

| X-007-08 | 7&8 | 20 | 160 | 90 | 14 | 110 | 60 | 5.3 | 2.00 | Format ProEngineer Solidworks Parasolid Iges Step Sat |

| X-007-10 | 10 | 25.5 | 200 | 110 | 20 | 140 | 70 | 8.4 | 4.51 | Format ProEngineer Solidworks Parasolid Iges Step Sat |

| X-007-13 | 13 | 32 | 270 | 140 | 22 | 140 | 70 | 14.0 | 7.61 | Format ProEngineer Solidworks Parasolid Iges Step Sat |

| X-007-16 | 16 | 36 | 280 | 155 | 28 | 190 | 100 | 21.0 | 12.4 | Format ProEngineer Solidworks Parasolid Iges Step Sat |

| HA40QA | 20 | 40 | 280 | 155 | 32 | 270 | 140 | 28.1 | 18.6 | Format Solidworks Iges Step Sat |

| HA45QA | 22 | 45 | 320 | 175 | 36 | 270 | 140 | 38.3 | 25.4 | Format Solidworks Iges Step Sat |

| HA50QA | 26 | 50 | 350 | 195 | 40 | 260 | 130 | 45.0 | 32.3 | Format ProEngineer Solidworks Parasolid Iges Step Sat |

| HA60QA | 32 | 60 | 430 | 230 | 50 | 350 | 195 | 67.0 | 63.9 | Format ProEngineer Solidworks Parasolid Iges Step Sat |

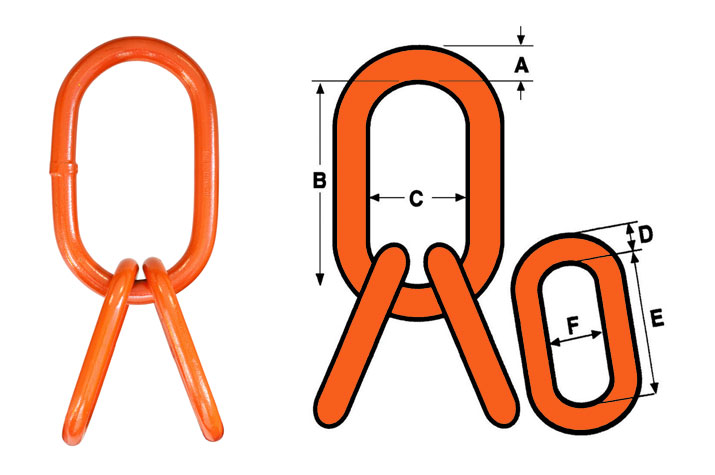

OVERSIZE SUB ASSEMBLIES FOR USE WITH 3 & 4 LEG CHAIN SLINGS

| Part Code |

Chain Size mm |

A mm |

B mm |

C mm |

D mm |

E mm |

F mm |

WLL tonnes |

Mass Kg |

CAD Files |

|---|---|---|---|---|---|---|---|---|---|---|

| HA23QA | 7 & 8 | 22 | 270 | 140 | 16 | 150 | 75 | 5.8 | 3.7 | Format ProEngineer Solidworks Parasolid Iges Step Sat |

| HA25QA | 10 | 25 | 270 | 140 | 20 | 140 | 70 | 8.83 | 5.3 | Format ProEngineer Solidworks Parasolid Iges Step Sat |