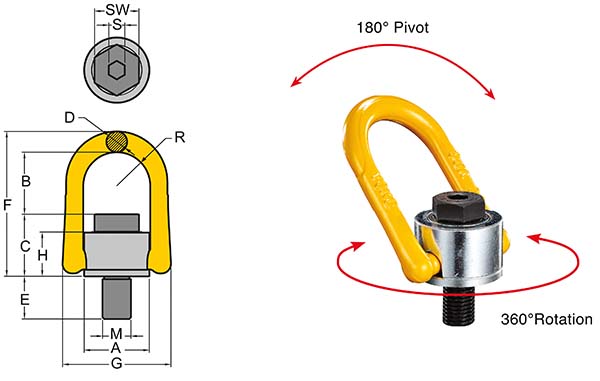

Yoke Swivel Hoist Ring - type 231 metric thread

- Rotates through 360° and pivots 180°, and simultaneously allows lifting from any direction.

- Manufactured from forged alloy steel, quenched and tempered and tested in accordance with EN1677-1.

- Load rated parts are 100% magnaflux crack detected & the individual forged parts & cap screw are traceable to Test Certification.

- Bolts are Metric thread (ASME / ANSI B18.3.1M).

- Proof tested to 2.5 times the WLL and Fatigue rated to 1.5 times the WLL.

- Design Factor 4 : 1

- All YOKE Lifting points meet or exceed all the requirements of ASME B30.26.

- Quick and simple assembly, just a tapped hole is required.

|

Part Code |

WLL (t) 5 : 1 |

WLL (t) 4 : 1 |

Thread M E |

Pitch DIN13 |

A mm |

B mm |

C mm |

D mm |

F mm |

G mm |

H mm |

R mm |

S mm |

SW mm |

Torque in Nm |

Mass Kg |

|

| 8-231-005 | 0.4 | 0.5 | M8 | 12 | 1.25 | 33 | 42 | 28 | 11 | 80 | 58 | 23 | 17 | 6 | 13 | 30 | 0.3 |

| 8-231-007 | 0.56 | 0.7 | M10 | 15 | 1.5 | 33 | 41 | 29 | 11 | 80 | 58 | 23 | 17 | 6 | 17 | 60 | 0.3 |

| 8-231-010 | 0.8 | 1.0 | M12 | 20 | 1.75 | 33 | 40 | 31 | 11 | 80 | 58 | 23 | 17 | 8 | 19 | 100 | 0.3 |

| 8-231-015 | 1.2 | 1.5 | M14 | 21 | 2 | 50 | 56 | 45 | 17 | 117 | 90 | 36 | 27 | 10 | 22 | 120 | 0.9 |

| 8-231-020 | 1.6 | 2.0 | M16 | 24 | 2 | 50 | 54 | 46 | 17 | 117 | 90 | 36 | 27 | 10 | 24 | 150 | 0.9 |

| 8-231-025 | 2.0 | 2.5 | M18 | 26 | 2.5 | 65 | 78 | 57 | 20 | 153 | 108 | 44 | 34 | 12 | 30 | 200 | 1.9 |

| 8-231-030 | 2.4 | 3.0 | M20 | 30 | 2.5 | 50 | 52 | 49 | 17 | 117 | 90 | 36 | 27 | 12 | 30 | 250 | 1.0 |

| 8-231-050 | 4.0 | 5.0 | M24 | 36 | 3 | 72 | 81 | 59 | 25 | 163 | 125 | 44 | 37 | 14 | 36 | 400 | 2.6 |

| 8-231-078 | 6.2 | 7.8 | M30 | 48 | 3.5 | 87 | 94 | 81 | 30 | 204 | 148 | 62 | 46 | 17 | 46 | 500 | 5.0 |

| 8-231-125 | 10.0 | 12.5 | M36 | 54 | 4 | 110 | 112 | 98 | 36 | 247 | 188 | 75 | 57 | 22 | 55 | 1000 | 9.6 |

| 8-231-156 | 12.5 | 15.6 | M42 | 63 | 4.5 | 110 | 101 | 108 | 36 | 247 | 188 | 83 | 57 | 24 | 65 | 1500 | 10.9 |

| 8-231-200 | 16.0 | 20.0 | M48 | 72 | 5 | 110 | 97 | 113 | 36 | 248 | 188 | 83 | 57 | 27 | 75 | 2000 | 11.6 |

| 8-231-220 | 17.6 | 22.0 | M56 | 84 | 5.5 | 123 | 116 | 121 | 36 | 274 | 202 | 91 | 64 | 27 | 85 | 2100 | 15.0 |

| 8-231-225 | 18.0 | 22.5 | M64 | 100 | 6 | 123 | 111 | 126 | 36 | 274 | 202 | 91 | 64 | 32 | 95 | 2200 | 16.3 |

USES

Swivel Hoist Ring uses can be as follows:

- New generation swivel hoist ring

- Lower profile and higher weight

- Suited for lifting objects with no obvious attachment points

- Mold and die handling

- Pump and valve handling

SWIVEL HOIST RING TYPE 231 WORKING LOAD APPLICATION FACTORS

|

|

|

|

|

|

|

|

||||

|

Number of legs |

1 | 2 | 1 | 2 | 2 | 2 | 3-4 | 3-4 | |||

| Load Direction | 0° | 0° | 90° | 90° | 0-45° | 45-60° | unsymm. | 0-45° | 45-60° | unsymm. | |

| Part Code | Thread | WLL tonnes | |||||||||

| 8-231-005 | M8 | 0.8 | 1.6 | 0.5 | 1 | 0.7 | 0.5 | 0.5 | 1.1 | 0.8 | 0.5 |

| 8-231-007 | M10 | 1.2 | 2.4 | 0.7 | 1.4 | 1 | 0.7 | 0.7 | 1.5 | 1.1 | 0.7 |

| 8-231-010 | M12 | 2 | 4 | 1 | 2 | 1.4 | 1 | 1 | 2.1 | 1.5 | 1 |

| 8-231-015 | M14 | 2.4 | 4.8 | 1.5 | 3 | 2.1 | 1.5 | 1.5 | 3.2 | 2.3 | 1.5 |

| 8-231-020 | M16 | 3.2 | 6.4 | 2 | 4 | 2.8 | 2 | 2 | 4.2 | 3 | 2 |

| 8-231-025 | M18 | 5 | 10 | 2.5 | 5 | 3.5 | 2.5 | 2.5 | 5.3 | 3.8 | 2.5 |

| 8-231-030 | M20 | 5.6 | 11.2 | 3 | 6 | 4.2 | 3 | 3 | 6.3 | 4.5 | 3 |

| 8-231-050 | M24 | 9.2 | 18.4 | 5 | 10 | 7 | 5 | 5 | 10.5 | 7.5 | 5 |

| 8-231-078 | M30 | 12 | 24 | 7.8 | 15.6 | 10.9 | 7.8 | 7.8 | 16.4 | 11.7 | 7.8 |

| 8-231-125 | M36 | 14 | 28 | 12.5 | 25 | 17.5 | 12.5 | 12.5 | 26.3 | 18.8 | 12.5 |

| 8-231-156 | M42 | 16 | 32 | 15.6 | 31.2 | 21.8 | 15.6 | 15.6 | 32.8 | 23.4 | 15.6 |

| 8-231-200 | M48 | 20 | 40 | 20 | 40 | 28 | 20 | 20 | 42 | 30 | 20 |

| 8-231-220 | M56 | 22 | 44 | 22 | 44 | 30.8 | 22 | 22 | 46.2 | 33 | 22 |

| 8-231-225 | M64 | 22.5 | 45 | 22.5 | 40 | 28 | 20 | 20 | 42 | 30 | 20 |