ROV Subsea Chain Block

The Hackett ROV compatible SS-C4 anti-corrosion subsea chain blocks meet and exceed the requirements of international standards

British Standard BS EN13157:2004 + AI:2009

American Standard ASME B30.16-2012

Australian Standard AS1418.2-1997

South African Standard SANS 1594:2007

NORSOK R-002: 2017.

William Hackett has taken its extensive knowledge of corrosion protection acquired in the supply of its specialist subsea range to the offshore sector and translated this technology to the newly developed second generation range of Hackett ROV SS-C4 anti-corrosion subsea chain blocks.

These hoists can be supplied in the following configurations

- Chain block working load limit capacities available: 3.2t, 5t, 10t, 15t and 20t multi fall units

- Single hook suspension unit

- Hot stab interface ISO 13628-8 3/8” BSP.1 Hot stab male receptacle.

- Fishtail direct drive interface

- D-link drive

- High performance waterproof grease giving superior rust and corrosion protection that will not separate, cake or wash out.

- Specialist subsea brake material

- Lightweight sturdy handles using 316L stainless steel.

- Operating temperature range -40°C to +55°C

- Stainless steel fixing and fasteners.

- 3D Models available.

All the above hoist configurations can also be supplied with the following options

- Calibrated Grade T (8) load chain to BS EN818-7 zinc plated

- Calibrated Grade T (8) load chain to BS EN818-7 DT9 corrosion coated

- Calibrated Grade S (6) 316L stainless steel load chain

- Complies with the Lifting Equipment Engineers Association ‘Code of Practice for Selection, Management, Use, Maintenance and Examination of Hand Chain Blocks and Lever Hoists in The Offshore Environment including Subsea’. Doc. Ref. LEEA 033 dated July 2014.

Features

- 500hrs + protection against salt spray tests according to ASTM B117

- Twin pawls as standard - captivated internally to prevent damage

- Heavy duty forged safety catches

- Stainless steel fixing used throughout the hoist

- Hook housing is bolt connected using cap head screws and nyloc nuts

- All internal hoist components fully corrosion protected

- Compact and robust design for easy handling

Performance and Testing

The Hackett ROV SS-C4 chain blocks have been fully tried and tested to include:

- Minimum Breaking Load - a minimum of 4 x the WLL

- The load chain anchor / end stop tested to at least 2.5 x the WLL with no restriction of either the brake or gears

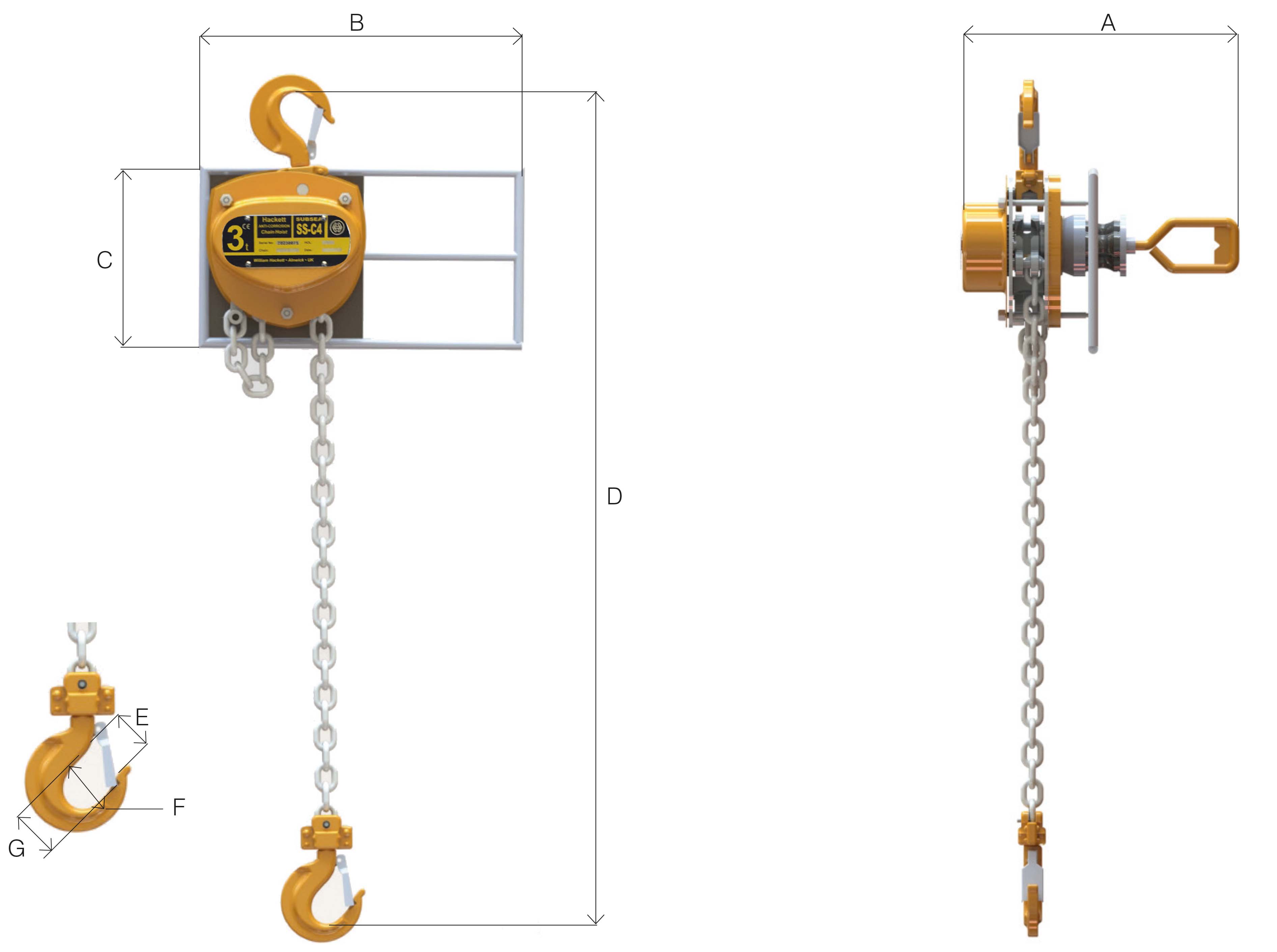

SPECIFICATIONS AND DIMENSIONS

|

Product Code |

WLL |

A mm |

B mm |

C mm |

D mm |

E mm |

F mm |

G mm |

Load Chain Dia. mm |

No. of Falls |

Max Torque Nm |

Revs/300m travel |

3m weight HOL out of water (kg) |

Extra Weight per M kg |

| 022.R.300.H1.P | 3.2 | 384 | 516 | 292 | 520 | 43 | 48 | 61 | 10.0 | 1 | 45 | 54 | 61 | 2.2 |

| 022.R.300.F1.P | 3.2 | 507 | 516 | 292 | 520 | 43 | 48 | 61 | 10.0 | 1 | 45 | 54 | 41 | 2.2 |

| 022.R.500.H1.P | 5.0 | 384 | 516 | 292 | 600 | 51 | 60 | 77 | 10.0 | 2 | 45 | 108 | 67.5 | 4.4 |

| 022.R.500.F1.P | 5.0 | 507 | 516 | 292 | 600 | 51 | 60 | 77 | 10.0 | 2 | 45 | 108 | 47.5 | 4.4 |

| 022.R.1000.H1.P | 10.0 | 384 | 516 | 292 | 760 | 53 | 85 | - | 10.0 | 4 | 50 | 165 | 117 | 8.8 |

| 022.R.1000.F1.P | 10.0 | 507 | 516 | 292 | 760 | 53 | 85 | - | 10.0 | 4 | 50 | 165 | 97 | 8.8 |

| 022.R.1500.H1.P | 15.0 | 414 | 516 | 292 | 1000 | 80 | 100 | - | 10.0 | 6 | 50 | 330 | 118 | 13.2 |

| 022.R.1500.F1.P | 15.0 | 537 | 516 | 292 | 1000 | 80 | 100 | - | 10.0 | 6 | 50 | 330 | 99 | 13.2 |

| 022.R.2000.H1.P | 20.0 | 429 | 600 | 292 | 1150 | 80 | 110 | - | 10.0 | 8 | 55 | 430 | 225 | 17.6 |

| 022.R.2000.F1.P | 20.0 | 552 | 600 | 292 | 1150 | 80 | 110 | - | 10.0 | 8 | 55 | 430 | 205 | 17.6 |